Blog

2022

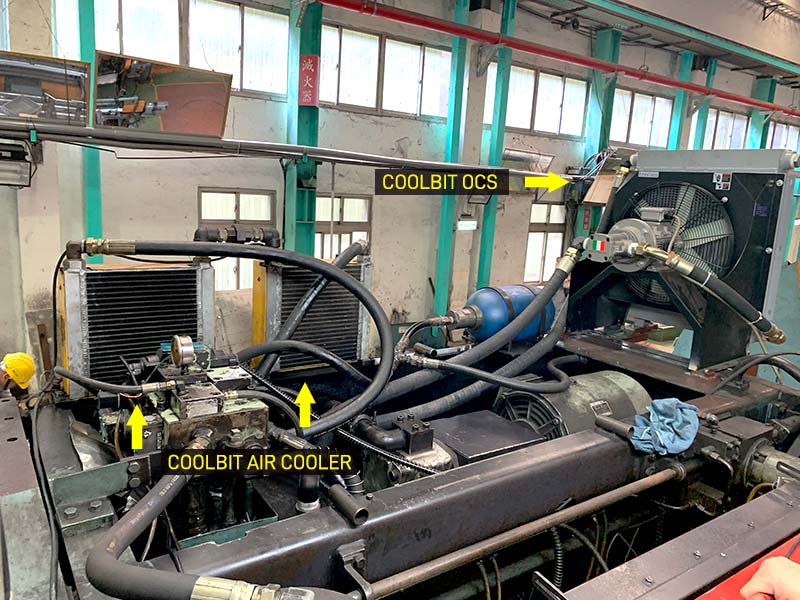

In Summer, Hydraulic shears additional OCS equipment for cooler

In response to the high temperature in summer,

Additional OCS cooling and cooling equipment is added to solve the inaccuracy of cutting due to overheating of the fuel tank and unstable pressure.

Hydraulic Cutting/Hydraulic Shearing Machine Customer Success Stories

Equipment rises in response to extreme heat in summer

CHUN YUAN STEEL CO., Ltd. added OCS active constant temperature oil cooler to solve the problems of "inaccuracy of hydraulic cutting and insufficient cutting pressure".

When there is a shortage of water resources, reducing the oil temperature through the "air-cooled" cooler is definitely an equipment conversion method that must be catered for now.

CHUN YUAN STEEL CO., Ltd. is a hydraulic shearing machine manufacturer with a large production volume.

For mass production operations, it is even more necessary to control the oil temperature of the hydraulic cutting equipment.

Reducing the oil temperature of the cutting equipment can increase the cutting pressure of the hydraulic shearing machine, improve the cutting accuracy, and prolong the service life of the cutting equipment, which is not easy to cause the equipment to stop.

High-frequency work use, the resulting high oil temperature will affect the cutting pressure.

When the cutting pressure is insufficient, it will cause problems such as insufficient cutting size and poor accuracy; especially in summer, the impact is more serious.

In order to solve the above problems, CHUN YUAN STEEL CO., Ltd. use COOLBIT OCS equipment to match the air-cooled oil cooler originally installed in the system to make the oil temperature cooling effect more effective.