Blog

07FEB

2023

2023

Airflow guiding oil filter fan assists plant air convection and reduces oil mist pollution

Blog

Airflow guides the oil filter fan to help the air convection in the large workshop

Plant air circulation, exhaust, and filtration three-in-one

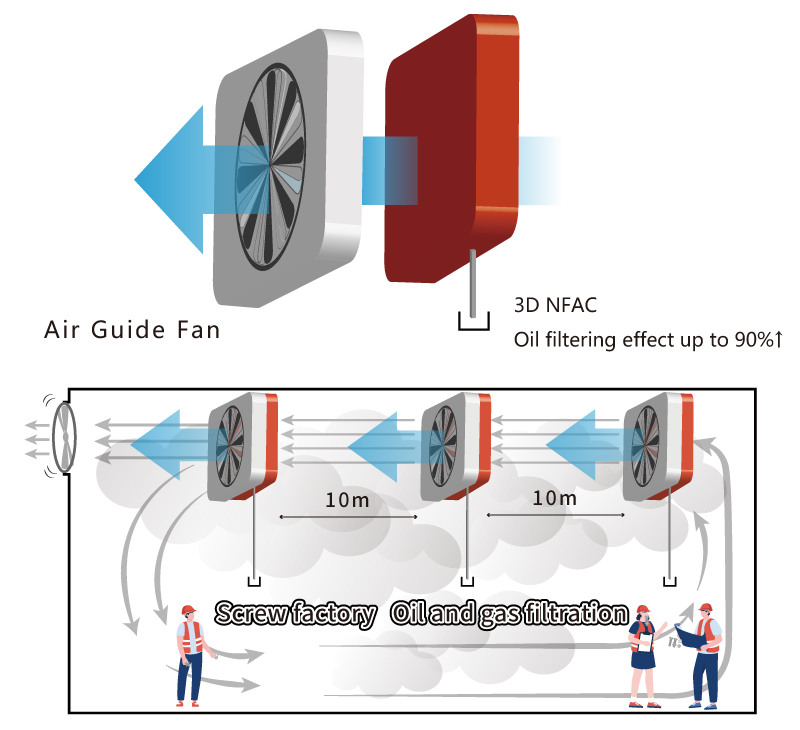

Solution 1: Filter the oil mist in the plant (using COOLBIT exclusive 3D negative dimension metal filter)

Especially the "screw factory" (serious oil and gas pollution, large space) environment is most suitable. After installation, there is no expenditure on consumables.

Using COOLBIT's exclusive 3D negative-dimensional metal filter screen, the oil filtering effect is over 90% according to the inspection standards of the Tokyo Fire Department, which can effectively filter out oil and gas pollution in the factory, and is easy to maintain.

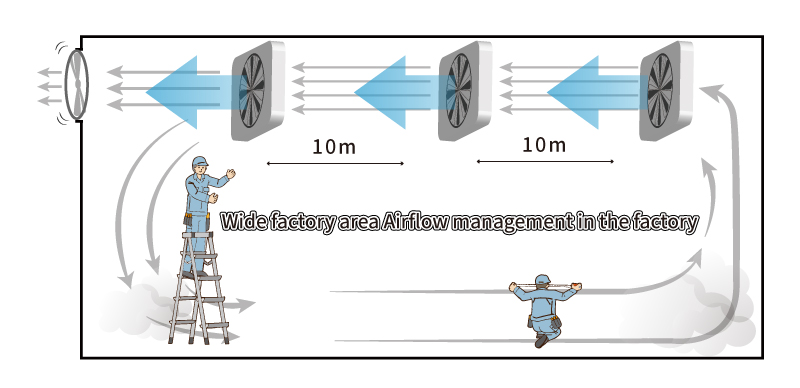

Option 2: Ventilation circulation in the factory to increase air circulation/accelerate air replacement

The air in the factory building is not circulated to solve the dead angle pollution of air circulation

Assist the factory exhaust fan to solve the problem that the exhaust fan cannot go deep into the factory area

Complete air filtration and ventilation problems in the whole plant. Assist the complete discharge of air in the factory.

Install "airflow guiding oil filter fan" every 10m, which can accelerate the discharge of air in the factory and increase the probability of air convection.

The oil mist pollution inside the factory is absorbed by the "airflow guiding oil filter fan" and the collected oil is discharged from the oil guide pipe.